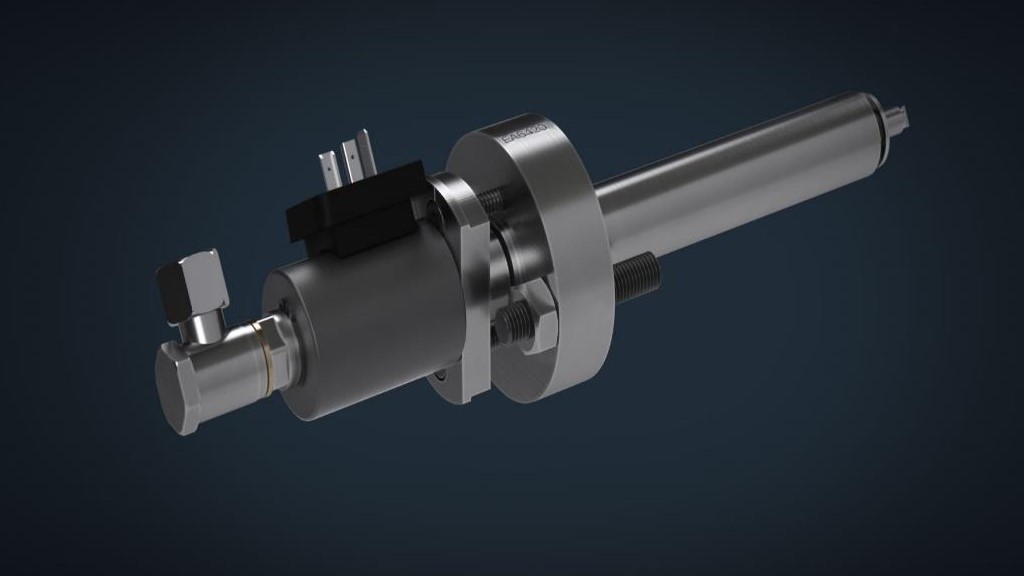

HJ SMARTLUBE 4.0

REVOLUTIONIZING LUBRICATION SYSTEM THAT INTEGRATES THE LUBRICATOR INTO A HJ SIP (SWIRL INJECTION PRINCIPLE) INJECTION VALVE. The compact design eliminates the need for an individual lubricator on each cylinder, meaning that the system consists of fewer parts, making maintenance and trouble-shooting faster and more user-friendly.

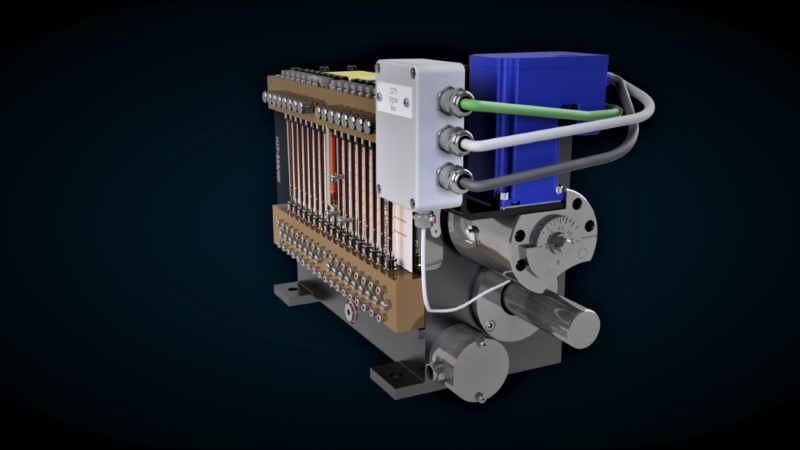

HJ LUBTRONIC 2.0

Electronically controlled cylinder lubricator allowing the injection of fresh cylinder oil during each piston stroke. Features our Delta-Timing algorithm that changes crankshaft angle at which cylinder oil injected and the Automatic Cleaning Sequence (ACS).

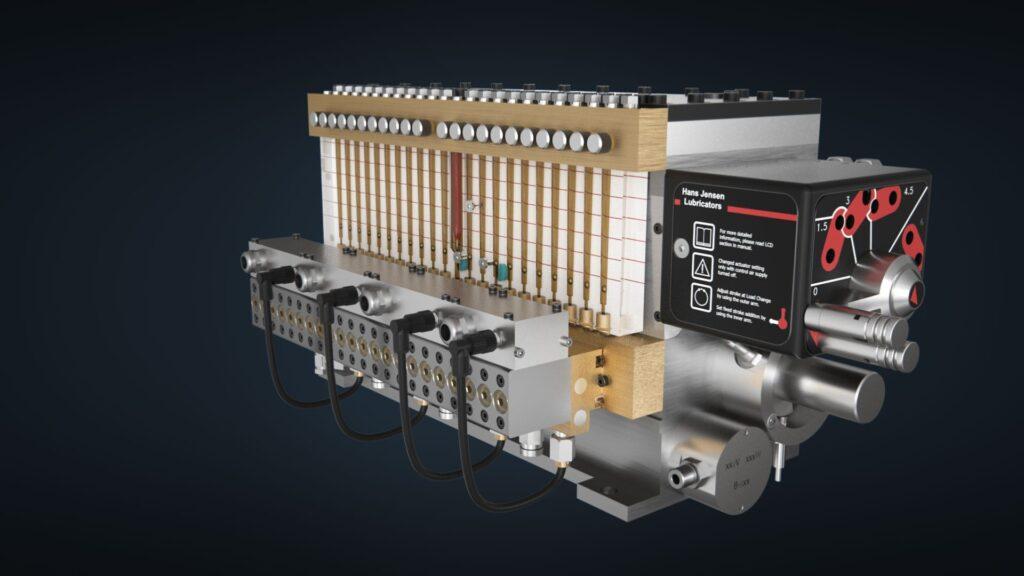

HJ X-TRONIC

Add-on electronic control system that can be retrofitted to existing mechanical lubricators, making the lubrication system electronically controlled with load and sulphur regulation. Regulation of consumption is achieved by an actuator which adjusts the stroke length automatically.

HJ MECHTRONIC

Electronic control system that can be retrofitted to existing mechanical lubricators, making the lubrication system electronically controlled with load and sulphur regulation. Regulation of consumption is achieved by a solenoid valve on each lube point.

Efficient cylinder lubrication reduces the friction between the piston rings and the liner which preserves fuel. This also minimizes the wear

inside the cylinder which extends TBO.

Then there is the distribution of the lubricant inside the cylinder, which is important, because it helps neutralize acids forming during

combustion.

Furthermore, proper lubrication cleans the cylinder from deposits and maintains a gas tight seal for better engine efficiency

The shipping industry’s ambitions for reducing CO2 emission are likely to follow several technological pathways, so a more flexible and

modular lubrication system is necessary.

Changes in engine design and the way engines are being run using standard lubrication systems have led to challenges in maintaining

cylinder conditions.

Furthermore, lower sulphur content in fuel oil means that the risk of cylinder liner and ring wear and scuffing has increased. These

challenges can be countered with a more flexible lubrication system.

It all comes down to optimizing productivity, reducing OPEX and lowering emissions.

Regardless of the age of your fleet, you can reap the benefits of HJL technology including reduced oil consumption by up to 60% and

significant reductions in CO2 and black carbon emissions.